Kueper is now a Master Distributor for all Kennametal Motorgrader products as well as Kennametal snowplow blades.

Download our brochure Download our brochure Download our brochure

Innovative Road Maintenance Tools

The widest selection and the most innovative road maintenance tools available in the industry. We offer carbide blades, grader blades, snowplow blades, and accessories. With our expertise in complex metallurgy we optimize performance therefore significantly decreasing production costs.

Our innovative road maintenance tools deliver productivity to customers seeking peak performance in demanding environments. We provide innovative wear-resistant solutions, through our advanced materials sciences, application knowledge, and commitment to a sustainable environment.

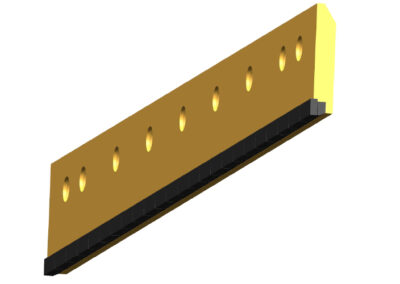

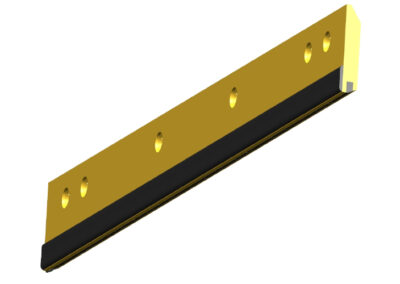

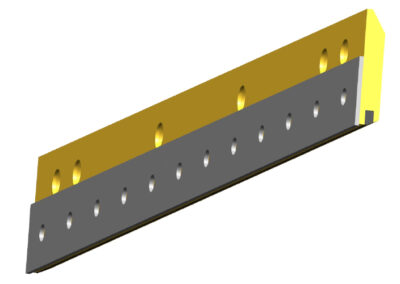

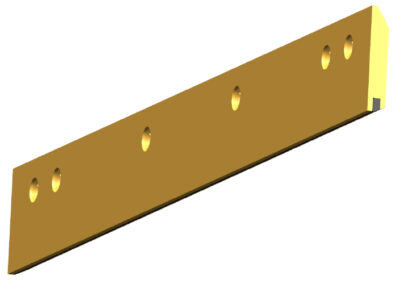

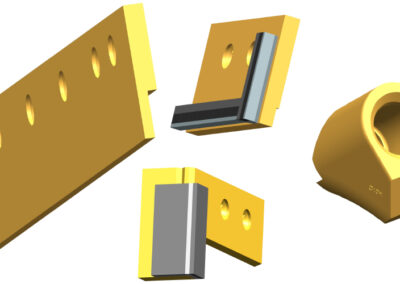

A Variety of Blade Styles to Match Your Conditions

Grader Blades for Plowing Snow

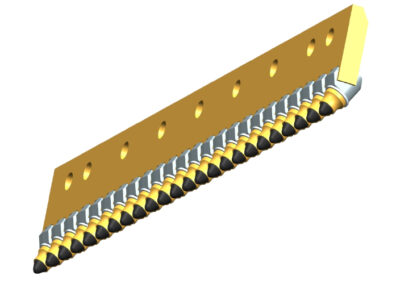

Kueper by Kennametal blades are easier to use and more versatile than competitive systems. The attack angle of the cutting tools is preset for ease of use, optimum tool rotation, and performance.

Our systems also accept a wider variety of cutting tool styles including both rotating and non-rotating type tools. As a result our systems can handle a wider variety of conditions. We also offer replacement tools and bits for older Sandvik motor grader systems.

The scarifier blade systems are designed so that just the cutting tools get replaced, not the blades.

Partially worn cutting tools can be easily repositioned along the moldboard consequently a straighter edge and balanced cutting tool wear life is achieved. An entire set of cutting tools can be changed by one person in a matter of minutes, even in the field, with no special tools required!

We encourage the safe use of its products. To help avoid personal injury or damage to tools, please follow these guidelines:

- Wear approved personal protection equipment, including eye and ear protection, steel-toed shoes, hard hat, and vest.

- Make sure tools are properly seated and securely retained.

- Do not strike cutting tools with metal objects. Carbide tips could shatter.

- Use a soft-headed hammer or other approved installation tools to insert cutting tools.

- Exercise care when removing tools.

- Inspect tools before each use. Do not use dull, cracked, burred, or bent tools.

- Operate all machines with safety in mind. Stand clear of machines in use, and make sure protective guards are in place.

- Do not change tools when the blade is moving.